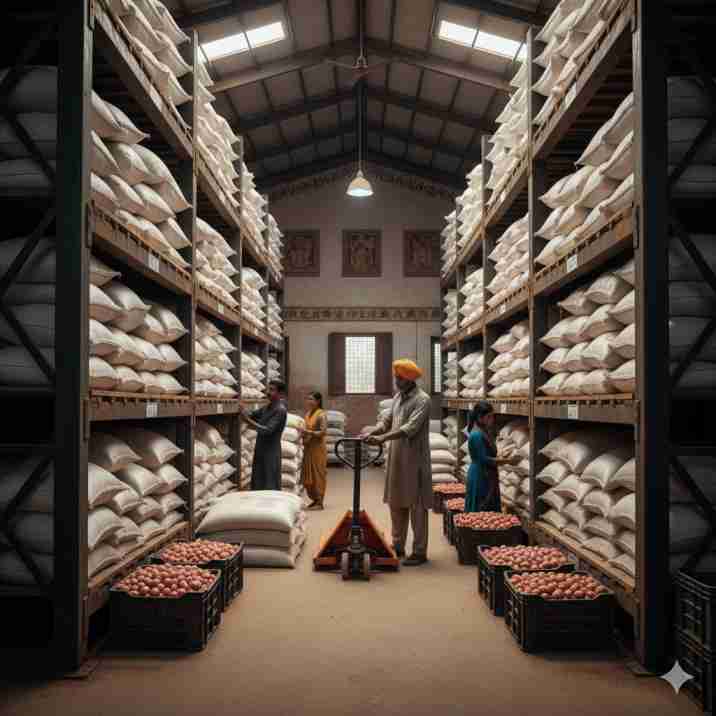

Selective Pallet Racking

- 100% SKU accessibility for high mix warehouses

- Configurable beam levels for varied pallet heights

Dhanvantri Farms provides advanced warehouse solutions, optimizing storage, workflows, and WMS for higher throughput and scalability.

Curated mix of accessibility and density tailored to SKU velocity and growth plans.

Alternating steps with visual context from dock to dispatch for fewer touches and higher accuracy.

ASN matching, barcode/QR capture, and quality checks ensure accurate receipts and traceability.

Rules-based slotting by velocity, size, and compatibility drives lower travel and better cube use.

Auto-replenish forward pick faces from reserve based on min/max and forecast signals.

Batch, wave, zone, or cluster picking with RF/voice for high accuracy and throughput.

Weight checks, labeling, and dock scheduling streamline trailer loading and turnaround.

Clear contrasts across storage, picking, replenishment, and energy.

Layout, slotting, WMS, and energy plan tailored to profile and growth roadmap.